Is there a perfect Fab design?

All modern 300mm front-end fabs are fully automated, have more or less the same functional areas, and are generally built on almost flat sites. All fabs have a cleanroom with similar temperature and humidity specs, a Subfab and need basically identical facility systems.

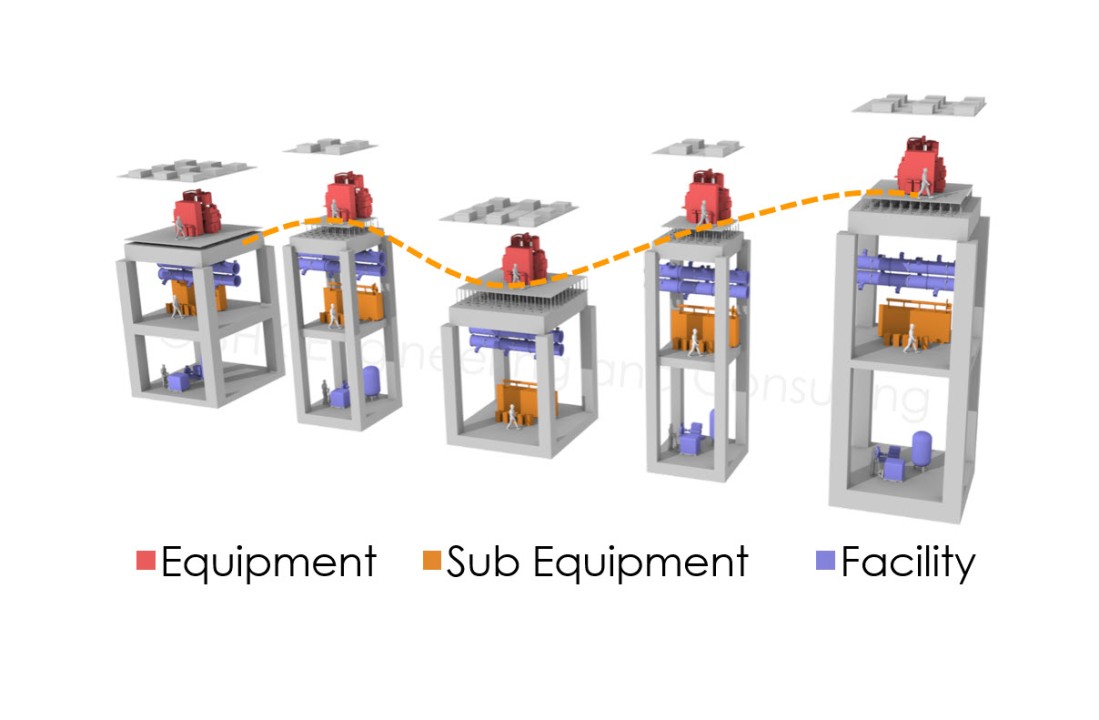

The picture above shows one cube each from the core of the fab building of 5 different existing Fabs. Almost no dimensions are the same. The heights of the waffleslab above ground level are very different, the grid spacing is different, raised floor or cleanroom heights are from low to high, and many, many very fundamental further differences not shown, such as the arrangement of the process laterals, the hook-up space management, the location of the facility centrals.

It is interesting to note that in our experience, fab buildings in Taiwan are much more similar to each other than they are in other countries.

Are the differences perhaps just because the best form factor for Fabs has not yet been found? After all, it took many iterations to find the perfect form factor for cell phones. Modern smartphones no longer differ so fundamentally in their dimensions and also in the layout of the internal components. It is interesting that also here the functions have become much more complex and extensive in the past decades and the inner structure has been condensed very much at the same time. Every inch³/mm³ of space is fought for here.

Shouldn’t we also fight for every ft³/m³ of space in Fab design? Reasonably compact buildings have great advantages because they require less of everything that makes a Fab project so expensive and complex to build.

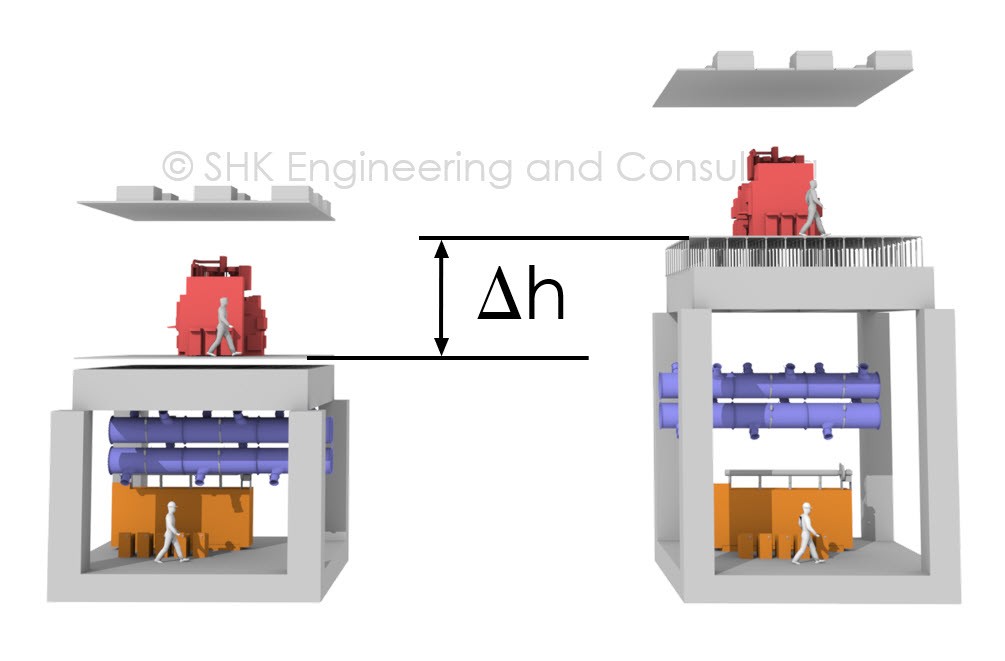

If you take a closer look at the height between the Subfab and the raised floor, for example, there are deltas of up to almost 12 feet or over 3 ½ m.

If one imagines a disk of this thickness on the plane with the most vertical installations in a fab, it would have a considerable value.

Modern 3D design is one key to more compact results. This is not only true for smartphones but also for many other things that have evolved so much.

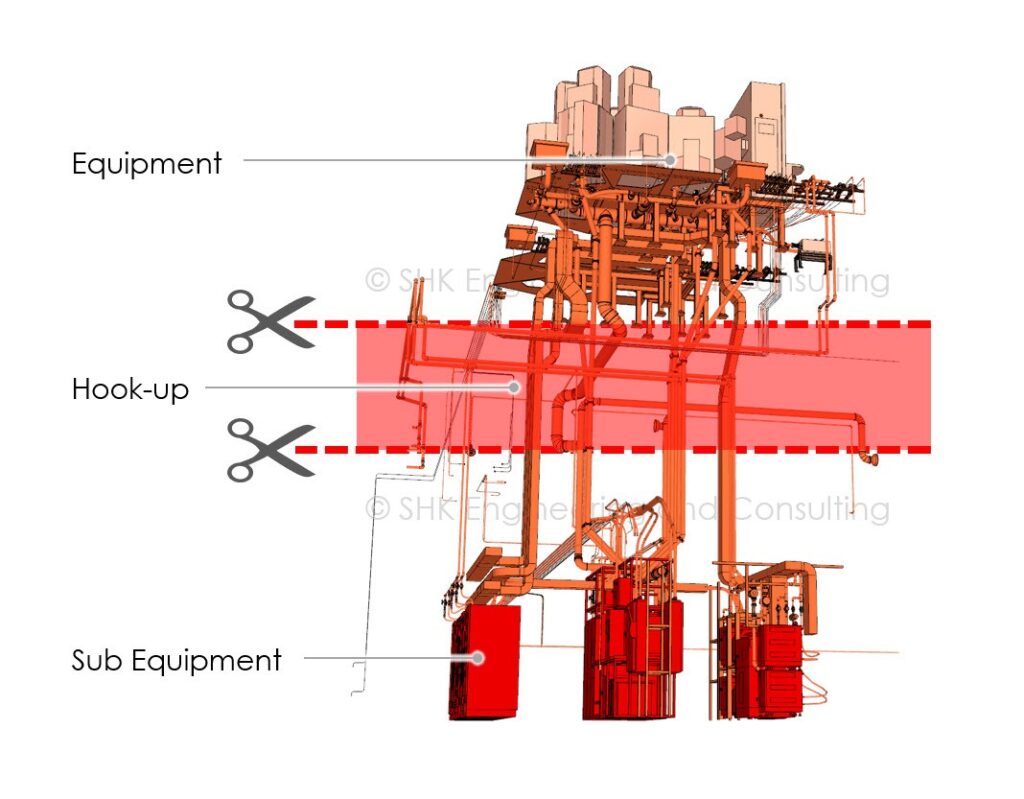

Another key is a very deep understanding of precise actual and future equipment demands. Looking back and using rough benchmark numbers will not be enough to design a modern compact Fab for future demands.

The SHK software SemiSoft® is designed to capture and manage all data relevant to the building and facility infrastructure. The 3D tools are so easy to use that they motivate to explore variations and work on them until the best solution is found. The DataCube© technology visualize the detailed Facility Utility Matrix on various hierarchies.

SemiSoft® is very useful for our current internal Fab Design R&D project. We are taking the time to examine the aspects of a perfect Fab building and try to assemble a virtual new Fab model from the results. In any case: this is fun and we learn a lot.

Comment on LinkedIn