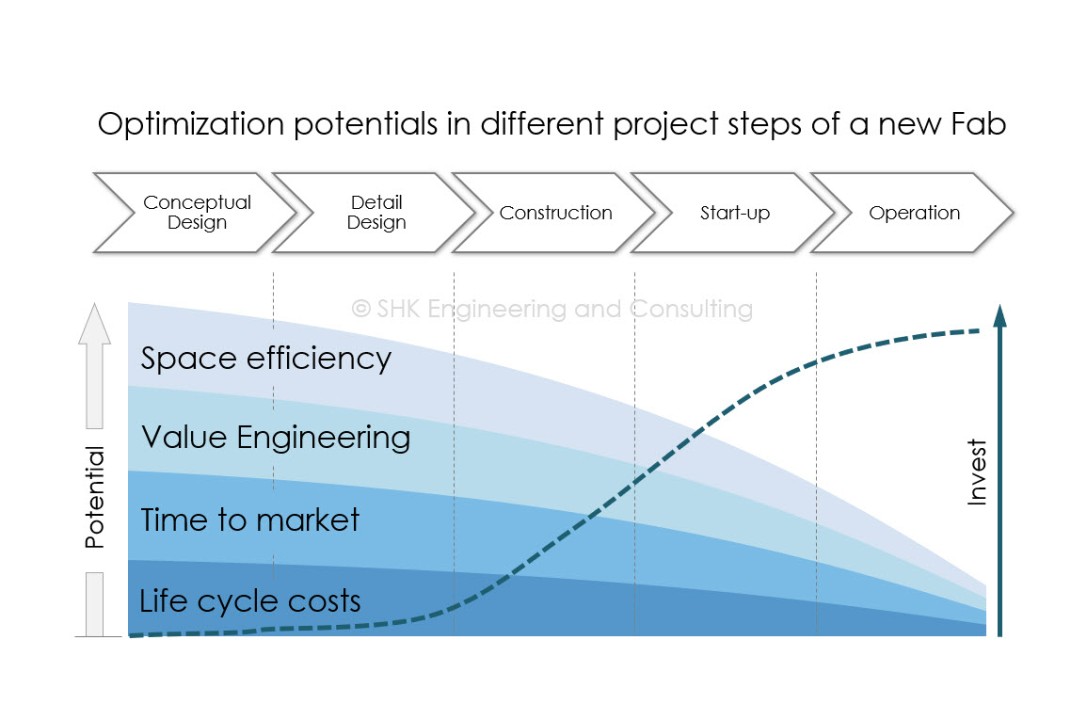

Good Design pays for itself

It happened to us in Fab start-up projects: SHK has been founded with experience in equipment engineering and Hook-Up design. We moved further into facility areas via Industrial Engineering and the design of AMHS and equipment layouts, until we finally designed all elements in the cleanroom and subfab. After this we started to design entire […]

Is there a perfect Fab design?

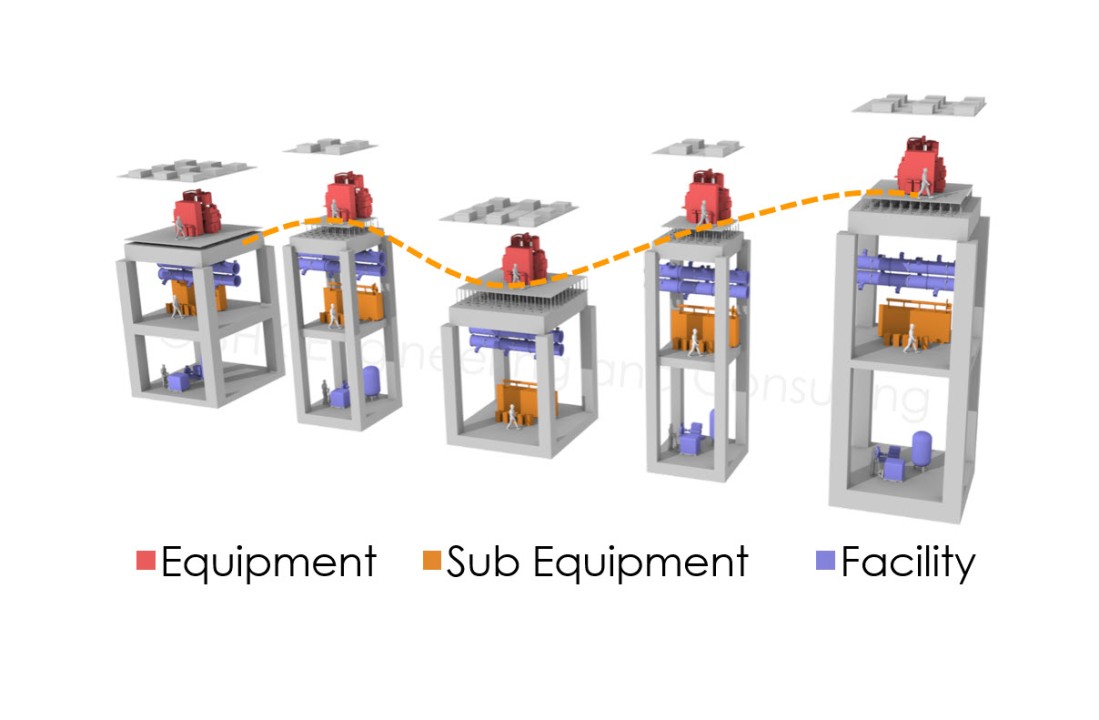

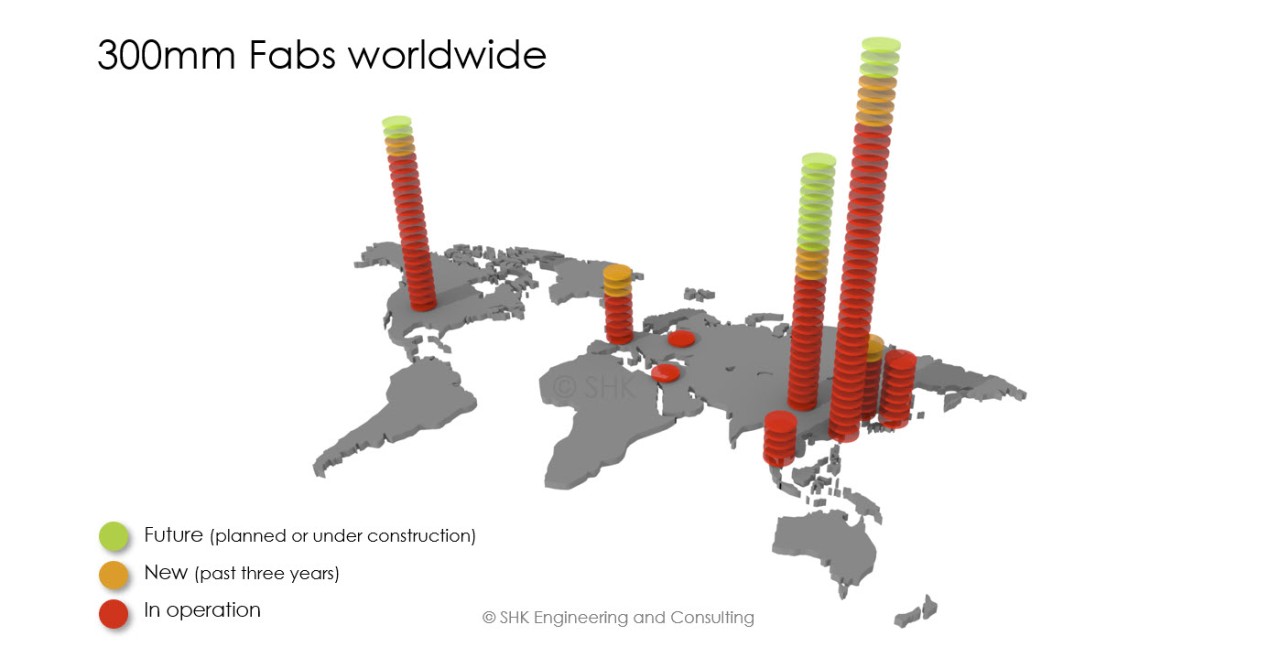

All modern 300mm front-end fabs are fully automated, have more or less the same functional areas, and are generally built on almost flat sites. All fabs have a cleanroom with similar temperature and humidity specs, a Subfab and need basically identical facility systems. The picture above shows one cube each from the core of the […]

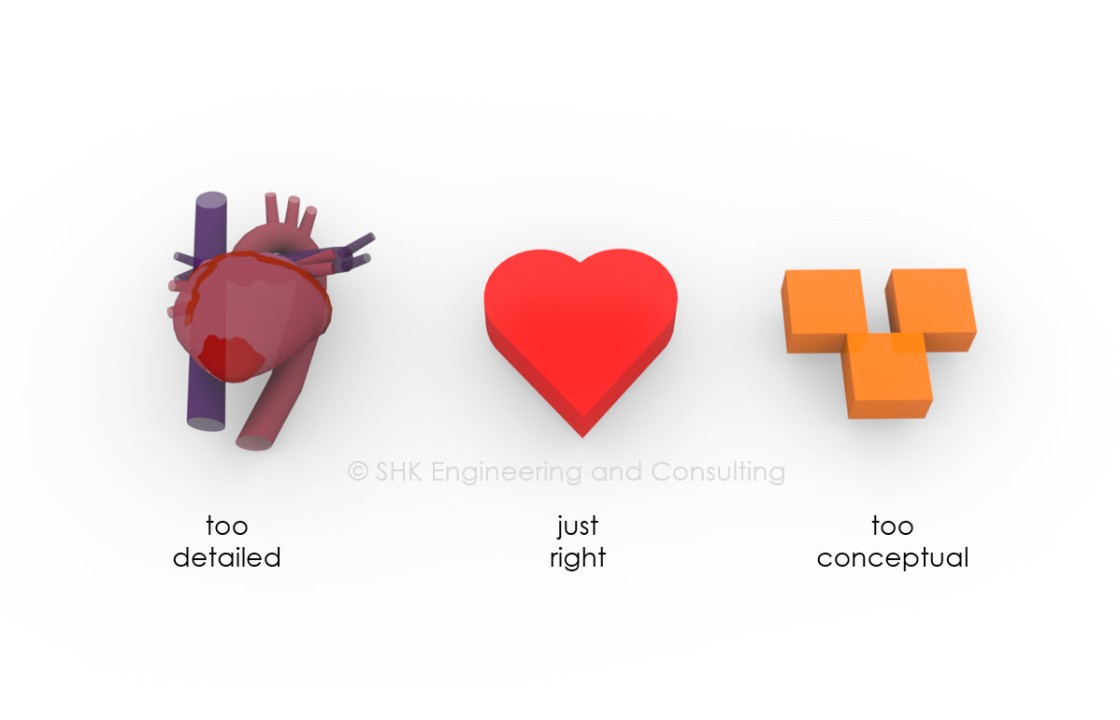

The level of detail should fit the task

When it comes to modern engineering and design, the buzzwords 3D and BIM are a “must”. What exactly stands behind these terms, however, is sometimes interpreted differently. A solid that looks like a pipe but has no references to material and technical data should not be called BIM and neither 3D pipework design. We at […]

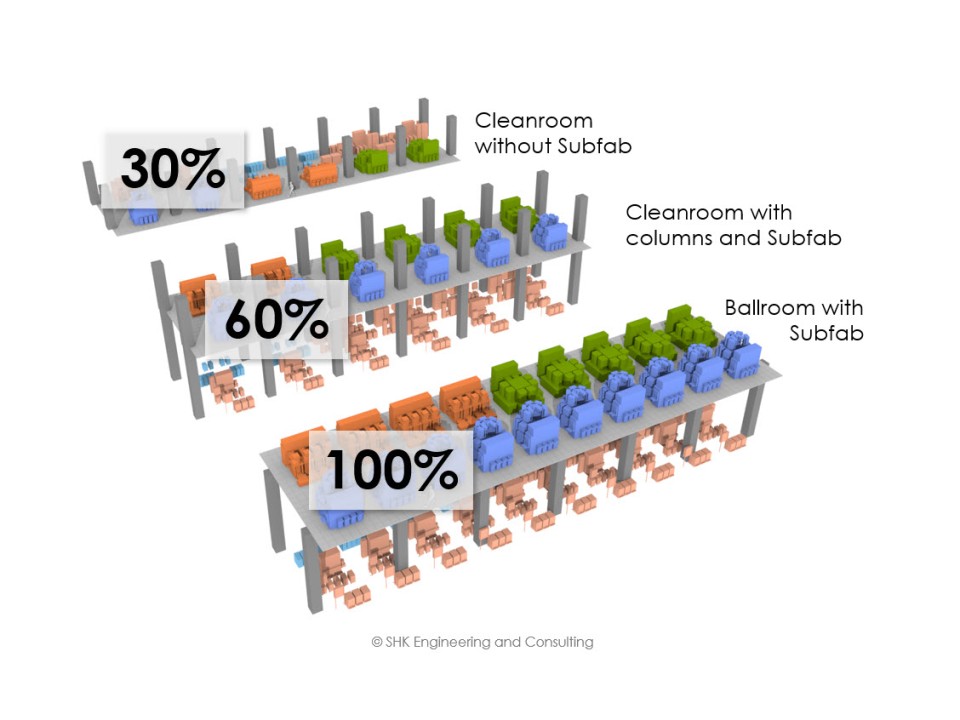

Different values of cleanrooms

The capacity of a Fab is directly related to the cleanroom size. But not only the area matters, also the type of cleanroom result in relevant space efficiency differences. See above, what happen if you look closer on a dry-etch space with about 5500 ft²/500 m². In this area 19 larger chamber equipments can be […]

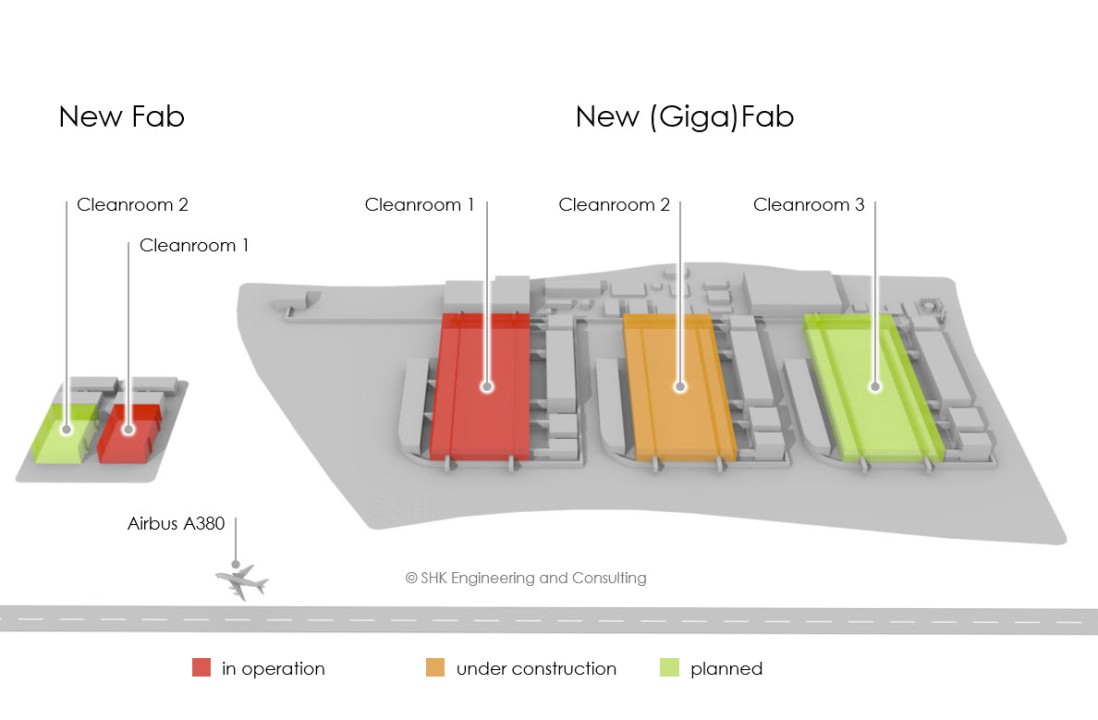

How big is Giga?

the illustration above show two site plots with manufacturing and support buildings with approximate external dimensions and in the same scale. The Fab on the left side was recently opened with buildings for Cleanroom 1. The builder says that this is the largest single investment in the history of their company. The right Fab is […]

So-called “wafers”

Semiconductors are manufactured in so-called “Fabs” in an so-called “cleanroom” on so-called “wafers”. When I started in the semiconductor industry in the 90s, I had to take a test-wafer-carrier with me on my first trip to Japan. The security at Munich Airport looked at the carrier with great interest and knew nothing about the term […]

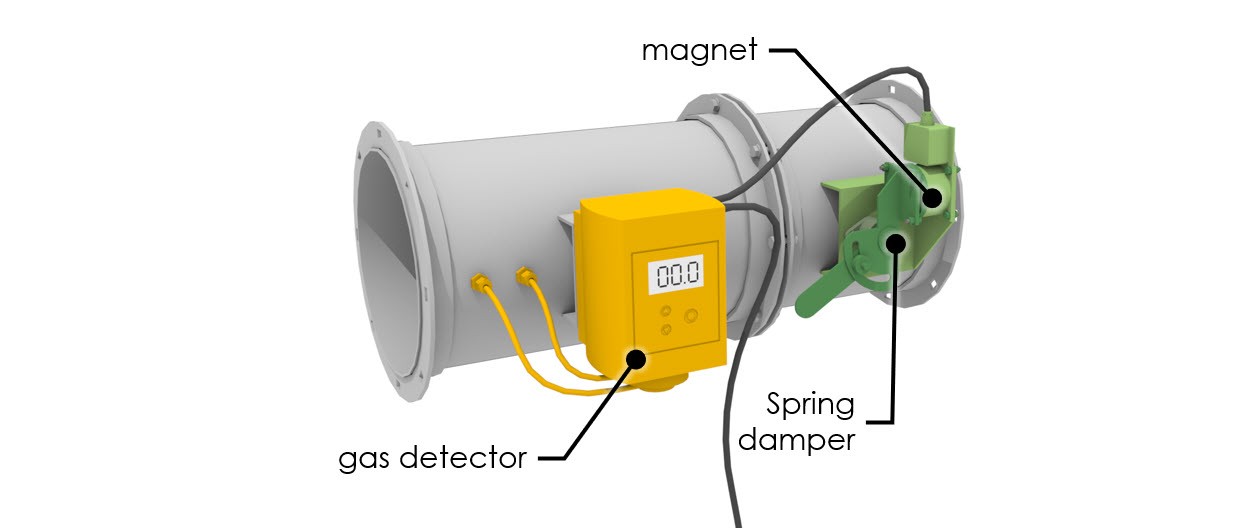

Three topics, one solution

First topic: Gas detection limitations because of dilution with exhaust air Gas detectors connected to equipment gas boxes are limited in their detection reliability due to the fact that the high extracted exhaust volume dilutes leaks by a factor of some hundred times or more. An example from one of our projects: A leak in […]

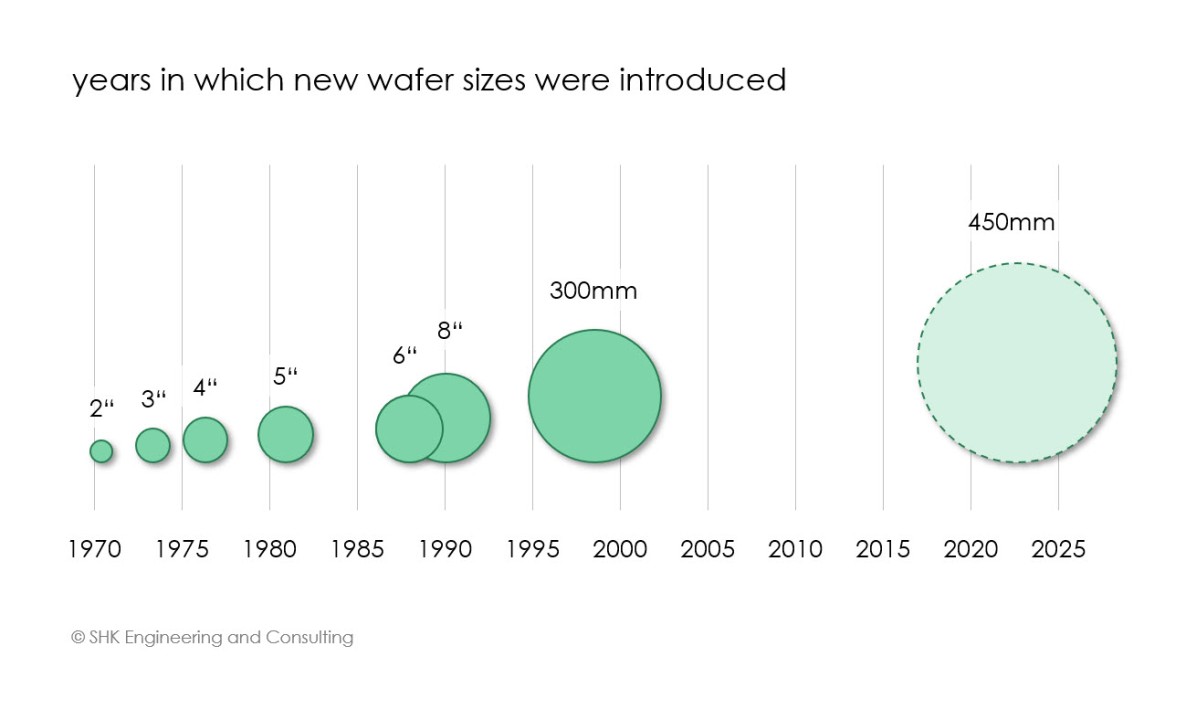

450mm ready

Fab buildings are getting more and more expensive. The lifespan of these valuable properties are measured in decades rather than years. Increasing wafer sizes has long been an essential tool for increasing a Fab’s manufacturing efficiency. Yield, shrink and manufacturing efficiency were always further measures. The time will come when the biggest potential in increasing […]